Safer Explosives

An Insensitive Munition (IM) is one that will not react violently in an accident or by enemy action, which will subject it to unplanned stimuli, such as heat, shock, and fragment or bullet impact. The global development of IM was initiated after a series of catastrophes resulting from accidental detonation of energetics or munitions during operation and storage in the 1980s. All these inadvertent events led to loss of life, combat and defence capabilities; and took millions of dollars to rectify the extensive damages.

ATREC’s formulation chemists have developed a wide range of insensitive energetic formulations which offer the best compromise of high performance and low sensitivity. These adaptable and matured energetic solutions outperformed conventional explosives (e.g. TNT and Comp-B) in insensitivity and lethality.

ATREC’s insensitive explosive formulations have been substance qualified to STANAG 4170 and exhibit excellent mechanical properties, thermal stability, ageing properties, as well as reduced vulnerability to shock and thermal threats.

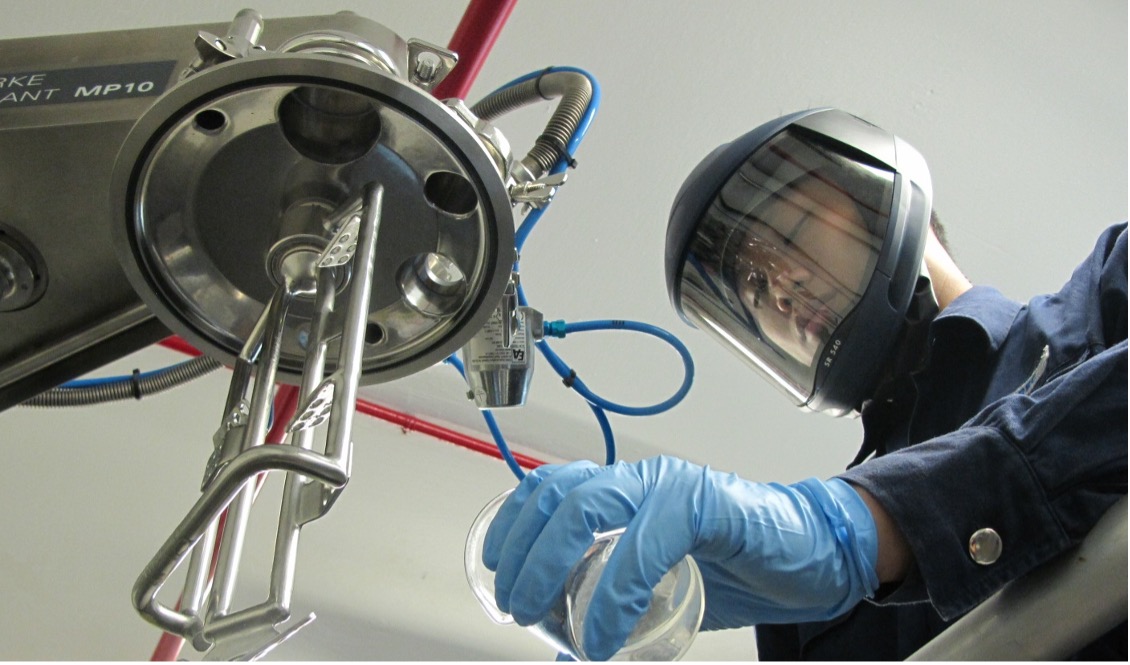

Processing of explosives using planetary mixer

New Energetic Processes

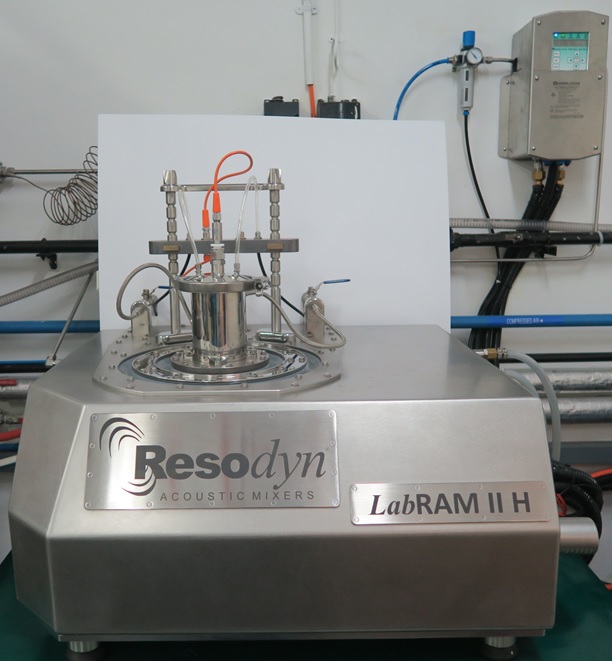

Processing of energetic materials using RAM Technology